cast sugar tongs

-

nigel le sueur

- contributor

- Posts: 227

- Joined: Sat Dec 24, 2005 6:38 am

- Location: Dorset

- Contact:

Cast Tongs were not made by Bucklemakers, out of the 50 plus pairs of cast tongs l have, to the best of my knowledge only two of the makers Montigue and Burrows registered as such during the period they entered marks at Goldsmiths Hall, and this was only for a short time in between changing from Smallworkers ( who made the majority of cast tongs)

Also the assay and makers mark were not always placed over the solder join.

What l feel is wrong is the Lion and incused Duty mark look so crisp it is most unusual, where the Lion is there appears to be re-soldering around it, Charles Hougham did "overstamp" other makers marks and if you look closley this might be the case here, either that or the C H does not fill the punch which Houghams punch did.

Regards

Nigel

.

Also the assay and makers mark were not always placed over the solder join.

What l feel is wrong is the Lion and incused Duty mark look so crisp it is most unusual, where the Lion is there appears to be re-soldering around it, Charles Hougham did "overstamp" other makers marks and if you look closley this might be the case here, either that or the C H does not fill the punch which Houghams punch did.

Regards

Nigel

.

I'm afraid I must disagree.

There were many bucklemakers who made cast tongs. Most had bucklemaker marks registered and all certainly have made both buckles and cast tongs in large surviving numbers

From our own collections alone we have BOTH cast tongs and buckles from each of the following

John Faux and George Love

John Faux (ofter Loves death)

Hester Bateman

Thomas Wallis

Henry Bickerton

George Smith

Joel Jacobson

Benjamin Montique

Thomas Eustace of Exeter

George Burrows

Samuel Hatton

Stephen Adams

Also the following marks, which cannot (despite dealers attempts to do so) be positively identified , where from our own collection , the identical mark is seen on both cast tongs and buckles

IL (probably James Lamb)

IS (probably James Stamp)

JP

WC

WT

IB

WP

IM

Hope this helps

.

There were many bucklemakers who made cast tongs. Most had bucklemaker marks registered and all certainly have made both buckles and cast tongs in large surviving numbers

From our own collections alone we have BOTH cast tongs and buckles from each of the following

John Faux and George Love

John Faux (ofter Loves death)

Hester Bateman

Thomas Wallis

Henry Bickerton

George Smith

Joel Jacobson

Benjamin Montique

Thomas Eustace of Exeter

George Burrows

Samuel Hatton

Stephen Adams

Also the following marks, which cannot (despite dealers attempts to do so) be positively identified , where from our own collection , the identical mark is seen on both cast tongs and buckles

IL (probably James Lamb)

IS (probably James Stamp)

JP

WC

WT

IB

WP

IM

Hope this helps

.

There are two more examples to be found on the very useful website of castsugartongs.co.uk.

William Harrison (in PR 1773 as bucklemaker ),early marks as smallworker, one mark specifically as bucklemaker 1781. Very well known and prolific bucklemaker . *(One of his apprentices, Samuel Moulton , who had originally been bound into the bucklemaking Cooke family was also in the PR 1773 as a bucklemaker, and entered at least one mark as such. Heal had either trade card or billheadings where Samuel described himself as bucklemaker. Samuel also signed the petition of the London bucklemakers to the Prince of Wales in 1791)

John Bourne. John Bourne & Thomas Bourne registered marks as bucklemakers at Queens Square, Bartholomew Close in 1775, and John Moore alone in 1787 at 1, Great Batholomew Close. However, like the website, I have a degree of uncertainty of the true identity of this IB mark. It appears on many top hinged tongs of the period and many people attribute it to John Buckle !!!

Thomas Northcote made also made a large number of buckles as well as tongs , and was associated by marriage and legal matters to several bucklemaking families.

.

William Harrison (in PR 1773 as bucklemaker ),early marks as smallworker, one mark specifically as bucklemaker 1781. Very well known and prolific bucklemaker . *(One of his apprentices, Samuel Moulton , who had originally been bound into the bucklemaking Cooke family was also in the PR 1773 as a bucklemaker, and entered at least one mark as such. Heal had either trade card or billheadings where Samuel described himself as bucklemaker. Samuel also signed the petition of the London bucklemakers to the Prince of Wales in 1791)

John Bourne. John Bourne & Thomas Bourne registered marks as bucklemakers at Queens Square, Bartholomew Close in 1775, and John Moore alone in 1787 at 1, Great Batholomew Close. However, like the website, I have a degree of uncertainty of the true identity of this IB mark. It appears on many top hinged tongs of the period and many people attribute it to John Buckle !!!

Thomas Northcote made also made a large number of buckles as well as tongs , and was associated by marriage and legal matters to several bucklemaking families.

.

I was wondering the span between the bowls. Don't most cast sugar tongs have a depression in the bowl area?

Short cast tongs have one advantage over cast tongs of regular length, they are less likely to break from strain (which is greater in a longer lever). I would imagine such breakage was one reason to move away from cast tongs and toward wrought.

.

Short cast tongs have one advantage over cast tongs of regular length, they are less likely to break from strain (which is greater in a longer lever). I would imagine such breakage was one reason to move away from cast tongs and toward wrought.

.

Sorry, misunderstood the word "span". I get dafter with age.

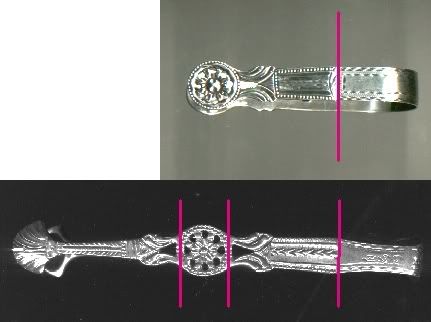

Distance between each "bowl" inner surface when no pressure is around 21mm currently. Max distance between inner surface of arms (near bow ) is 26mm.

Virtually all cast ( and other tongs ) had concave bowls - I THINK produced by hammering on a block rather than being cast as a curved surface . The bowls of this pair have been cast, then holes drilled. I agree with you- it's a good clue - but what to I'm not sure.

.

Distance between each "bowl" inner surface when no pressure is around 21mm currently. Max distance between inner surface of arms (near bow ) is 26mm.

Virtually all cast ( and other tongs ) had concave bowls - I THINK produced by hammering on a block rather than being cast as a curved surface . The bowls of this pair have been cast, then holes drilled. I agree with you- it's a good clue - but what to I'm not sure.

.

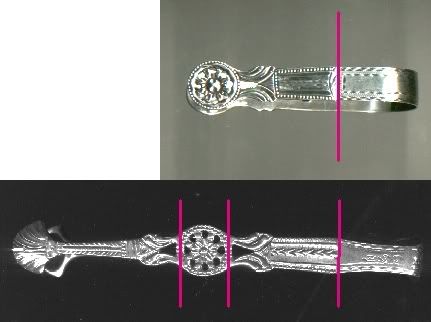

The mystery as to these tongs has taken another twist . Graham Hodges , in examining some of my wife's tongs pointed out that the circular feature used as a bowl for these tongs was also used as decoration in the arms of another. (Sounds like Barbara Cartland). So was this a cut down of a longer pair, with the bowls and the arms removed ? Hence no resoldering necessarily. All three of us (wife , Graham and me ) examined the ends of the "bowls" and came to the same conclusion - No. The patination and finish indicated it had almost certainly started life in this form. If it had altered it had been done by a very good silversmith and at least a hundred years ago. The advantage of a good patina !

But more revalations . The full lenght pair were not a three piece construction but of seven piece construction.

It would appear that this was originally made in this form - but for what - we still do not know. Both pairs are by Charles Hougham , the full size pair being pre duty, the smaller have the incuse mark of 1784 -1786

.

But more revalations . The full lenght pair were not a three piece construction but of seven piece construction.

It would appear that this was originally made in this form - but for what - we still do not know. Both pairs are by Charles Hougham , the full size pair being pre duty, the smaller have the incuse mark of 1784 -1786

.